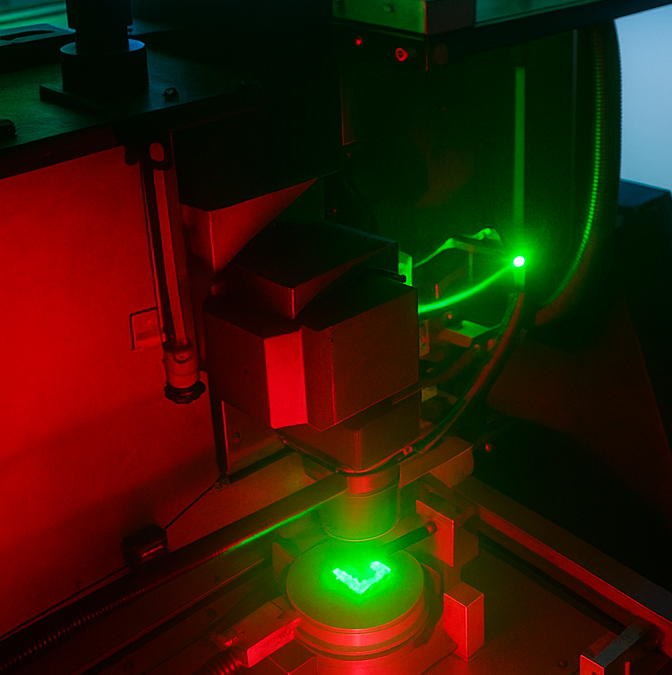

Resonant Scanner and Laser Technology

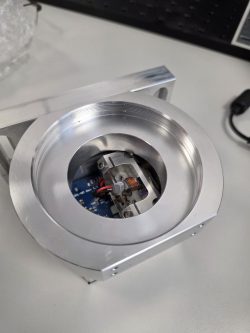

The resonant scanners developed and manufactured by FEMOTECH offer the highest level of precision, speed, and stability.

With scan frequencies of up to 24 kHz and deflections of ±10 degrees (optical), they are among the most powerful of their kind on the scanner market. The precise tuning of mechanical and material properties ensures maximum efficiency, repeatability, and long-life cycle.

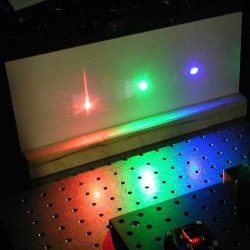

A key component of these scanners is our flat, rigid mirror elements that remain undeformed even at high frequencies and deflections, thereby guaranteeing optimal beam quality. Their special coatings achieve reflectance of up to 99.99%, making them suitable for both broadband and wavelength-specific applications. The high reflectivity optimizes efficiency in optical systems and allows scanning at high power levels.

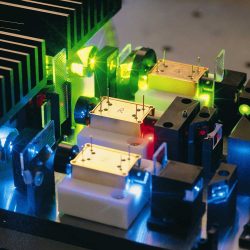

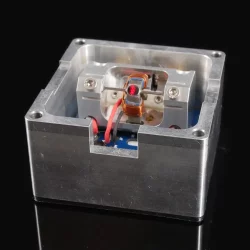

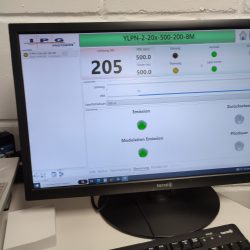

Our resonant scanners feature a high-precision amplitude control that guarantees optimal reproducibility of scan results. Additionally, our systems can be operated at fixed frequencies (Fixed Frequency Mode [FFM]), which enables synchronization with asynchronously pulsed lasers.

To achieve this, we developed an FPGA-based electronic control system that keeps the scanner in resonance, tunes its frequency, and measures its mirror position. The control electronics achieves an internal real-time resolution of 0.8 ns, which is used to generate all external trigger and synchronization signals. A programming API is provided for controlling the scanning system, which can be used in custom applications.

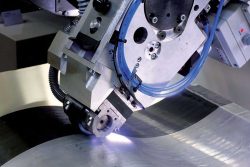

Our scanners are used in laser marking for precise and fast inscriptions, as well as in surface processing for microstructuring and material removal. In addition, they are applied in micromachining, microscopy for high-resolution imaging, and LiDAR technology for three-dimensional environmental analysis.

Manufacturing is carried out with the highest standards for dimensional accuracy and alignment. Careful final inspections ensure consistently high quality.

Application areas for our scanners

Our resonant scanners are used in a variety of applications:

- Laser marking – precise and fast marking of a wide variety of materials

- Surface processing – microstructuring and targeted material removal

- Micro-material processing – control of highly precise machining processes

- Microscopy/OCT – high-resolution imaging with fast scan speeds

- LiDAR applications – precise three-dimensional sensing of environments

Technical requirements and performance features

To meet the high demands of these applications, our scanners fulfill the following essential criteria:

- Highest precision – exact positioning for fine structures and repeatable processes

- Flexibility – dynamic adjustment of amplitude during operation. Fixed-frequency (FFM) or PLL operation

- High speed – efficient processing through high scan frequencies

- Stability and repeatability – consistent precision even during long-term operation and changes in ambient temperature

- Undistorted beam deflection – flat and rigid mirror elements for optimal beam quality

- Efficient energy transfer – high reflectivity for optimal power utilization. high duty cycle

Our scanning systems can be individually adapted to a wide range of applications. In doing so, different mirror sizes, scan frequencies, and coatings can be supplied.

We are happy to assist you in selecting the optimal system configuration for your needs.