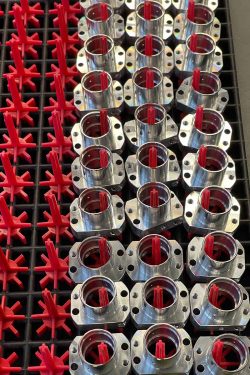

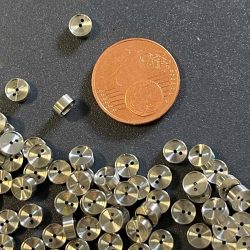

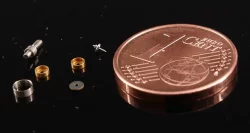

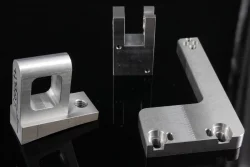

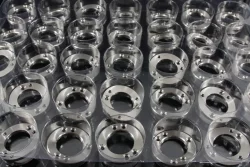

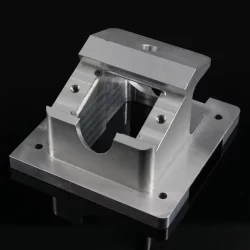

FEMOTECH GmbH manufactures high-precision turned and milled parts with micrometer-level precision, according to customer specifications. Our components and assemblies are used in a wide range of industries, including the medical, laser, and analytical technology sectors, as well as optics and precision engineering. We manufacture turned parts with diameters from under 1 mm up to 65 mm through spindle, and up to 140 mm in chuck. In addition, 5-axis milling can produce parts up to a size of 100 mm × 150 mm. We process a wide variety of materials, including:

- Aluminum

- Stainless steel

- Brass

- Arcap

- Plastics

- Nickel silver

- Free-cutting steel

- Copper

- Tempered steel

If desired, we are happy to advise you on material and surface selection for your specific application. We also assist you in developing and realizing your component. With our comprehensive expertise in design, development, and manufacturing, we are able to master even complex technical challenges and turn your ideas into finished components.

In our design process, we use SolidWorks™, a powerful 3D CAD software that offers a wide range of design tools and enables rapid creation of digital models.

Surface treatments or hardening processes are carried out through our partner companies.